In everyday life, people talk about Styropor, but we mostly refer to expanded polystyrene (EPS) or polypropylene (EPP), as well as copolymer (PS/PE). They all belong to the group of foam plastics. Due to their versatile properties, formability and individual density, these materials can be used for custom-made products and high-tech applications.

INDIVIDUAL SOLUTIONS

We give your ideas a form

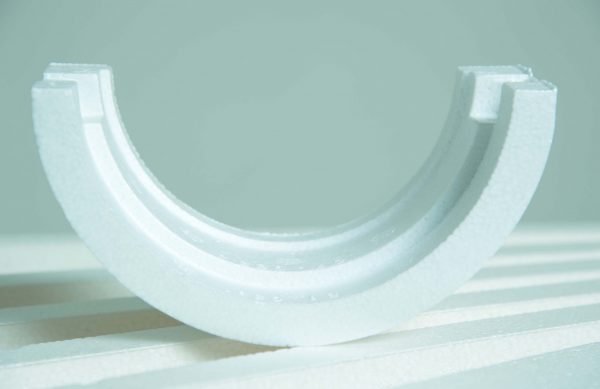

Tailored to your specific requirements, we produce molded parts up to a size of 1,480 mm x 1,280 mm and in densities of 18 – 410 kg/m³. Whether soft shell or firm core – you decide. We analyze the task with you and then take over all further steps from the planning to the construction of the molds to the final product. With our many years of know-how, we are the right partner for you.

APPLICATIONS

The solution for your application

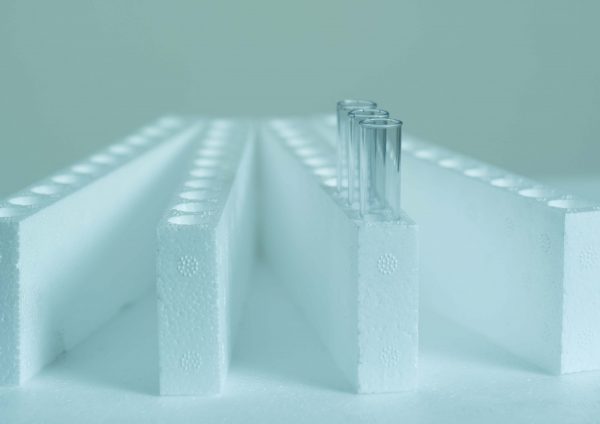

EPS, EPP as well as PS/PE have long been a highly valued and diversely used material in the construction industry. With molded parts you save time and costs and can plan precisely.

Depending on the requirements, technical molded parts have to perform special tasks. EPS, EPP as well as PS/PE combine the best properties, whether functional safety at high temperatures, resilience after static and dynamic loads and many more, and are therefore real problem solvers for highly specific requirements.

The pharmaceutical industry is mainly concerned with the safe transport of highly sensitive substances that must be protected and insulated at the same time.

EPS, EPP as well as PS/PE are harmless to health and therefore ideal for food storage. Warm things stay warm and cool things stay cool.

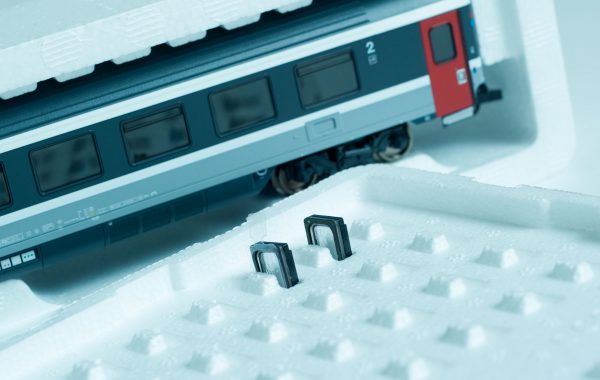

Many things require an individual fit. To ensure that products arrive at their destination safely and without damage, the packaging must be precisely tailored to the product and adapt to its particular characteristics.

Lost foam is a special manufacturing process for producing cast metallic components with geometries that are structurally demanding. The use of vaporizable foam patterns in an undivided mold enables near-net-shape, burr-free and dimensionally accurate castings with excellent surface quality.

Cores made of EPS are particularly suitable for this purpose as shaping placeholders. During casting, the incoming hot molten steel vaporizes the foam model and at the same time precisely fills the resulting cavity. This creates an exact metallic replica of the foam model.

PROPERTIES

informal.malleable.formtech

Expanded polystyrene (EPP), polypropylene (EPS) as well as copolymer (PS/PE) are characterized by their versatile properties.

High compressive strength with low weight. 60 – 200 kPa at 10% compression.

Insensitivity to moisture – water absorption is < 5%. Water vapor diffusion resistance number μ ranges from 20 to 100.

98% air and light as a feather. Depending on the specification, the molded parts have a bulk density of 15 (building insulation) to 90 kg/m³ (bicycle helmet).

Excellent thermal insulation due to low thermal conductivity of less than 0.04 W/m-K. Warm things stay warm and cool things stay cool.

It can be produced in many color variations, from bright yellow to deep green.

Very good chemical resistance to aqueous alkalis and mineral acids.

The raw material is biologically neutral and therefore suitable for food and pharmaceutical applications.

Environmentally friendly and 100% recyclable. Fuel consumption is reduced, Co2 is released less, energy consumption and therefore greenhouse gas emissions are reduced.

Your contact persons are: